Company

The Company I.C.P. is located in the north of Italy, in Piedmont region. It was founded in 1980 as a family business, whose main activity was the production of wiring for the electrical appliance and electromechanical sector. Since 1984, the company specialized in design and production of wear indicators for friction materials for disc and drum brakes of cars, industrial vehicles and motorcycles, as well as wiring in the same sectors.

This activity, thanks to the curiosity and passion of the founder, was accompanied in 1988 by the importation of Chickinox ultralight aircraft and the following year I.C.P. started marketing and sales of ultralight aircraft in aluminum alloy produced by Zenair.

In 1990 I.C.P. start producing with a licence agreeement the aforementioned aircraft and starting from 1996, while continuing the collaboration with Zenair, I.C.P. begins to design and produce its own aircraft with unique characteristics of robustness and versatility, now known worldwide for their high safety standards.

Over the years I.C.P. has become an SME of international importance, thanks to investments in R&D and constant innovation, continuing to develop products in both the automotive and aviation fields.

As a player in the automotive sector, I.C.P. is a certified supplier of original equipment components and original spare parts for the world's major brake and friction material manufacturers and actively collaborates with them on the development of wear indicators for new braking systems.

This activity represents approximately 50% of the company turnover, of which 10% is reinvested in R&D every year.

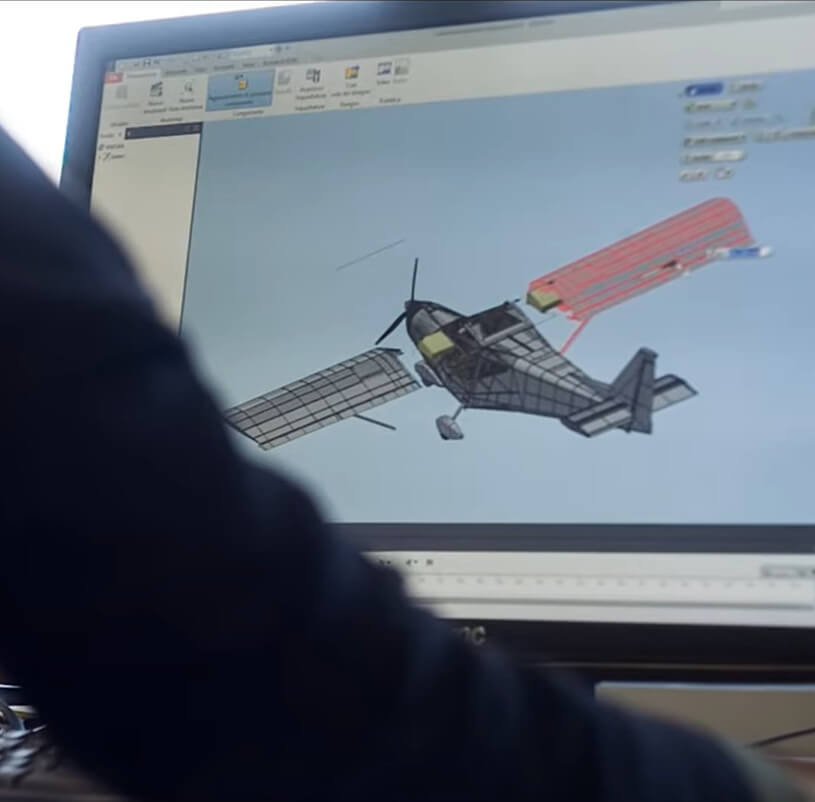

The other half of the business is the design, development and production of ultralight aluminum alloy aircraft. I.C.P. has developed over the years a highly technological product industrialization process, making a substantial economic investment in numerical control 4.0 machinery, such as laser cutting, punching, 5-axis lathe, thanks to which all the aircraft details are mass-produced. This choice made possible to optimize costs and facilitate the assembly of the aircraft, which are sold not only ready to fly but also in kits or assembly boxes, all over the world. This is the reason why is essential to guarantee perfect interchangeability of the parts.

This production strategy has contributed, over the years, to making flying economically accessible to many enthusiasts, while simultaneously recording notable company growth.

Our growth over the years

Over the years, together with the company, the need to expand the production plant has also grown, in order to make room for modern machinery, better organization of the warehouse (in the perspective of certifications especially in the aeronautical field) and new projects.

In September 2009, I.C.P. inaugurated the new headquarters in Castelnuovo Don Bosco (AT), a modern 10,000 m2 plant with a 143Kw photovoltaic panel system, installed both on the roof of the main factory and on the hangars, which allows the company to be energetically self-sufficient. The entire production plant is thermoregulated to guarantee maximum dimensional precision of the parts produced with cutting-edge machining centers.

Next to the factory plant I.C.P. has created a 700 m airfield which is used for testing the aircraft produced, to receive customers for maintenance and for the flight school managed by the local Aero Club.

Projects in progress

In 2010 we undertook the design of an aeronautical engine; it is a project born and developed entirely within the company. It is an innovative engine because it has double electronic injection and thanks to some patented technological solutions, it develops over 130 horsepower while consuming 70% of the fuel compared to its main competitor. After years of experimentation, changes in production technologies and improvements, we are finally working on the pre-series of 10 examples in the definitive version.

Another project, partly proudly completed, is a new aircraft model, also of metal construction, which we have called Ventura. It is a very versatile aircraft that adapts to 3 different configurations to embrace a large and heterogeneous market. Since a few years, we are developing and selling the 2-seater STOL ultralight version and the 4-seater version which is positioned in the experimental - amateur built category, while we are still working on the most challenging part of this project: the version certified according to EASA requirements CS23.

In the meantime, we have also developed a restyling of our most famous ultralight model, giving life to the Savannah SR, in order to combine some aesthetic improvements with adaptation to the most recent regulations.

Certifications

I.C.P. holds important patents in both the automotive and aeronautical sectors and was one of the first companies to obtain the ISO9001 certification in the aeronautical sector for the design and manufacturing of ultralight, LSA and Experimental aircraft and their kits.

I.C.P. has organized a quality management system in compliance with the IATF 16949 technical specification for the design and manufacturing of sensors for disc and drum brakes and UNI EN ISO 9001:2015 for the design and manufacturing of brake sensors and electrical wiring for vehicle use.